Sunlight is the ultimate source of energy; the packet of energy is known as photon. The invisible part of sunlight Ultra Violet rays needed for stamp making purpose.

Raw materials:

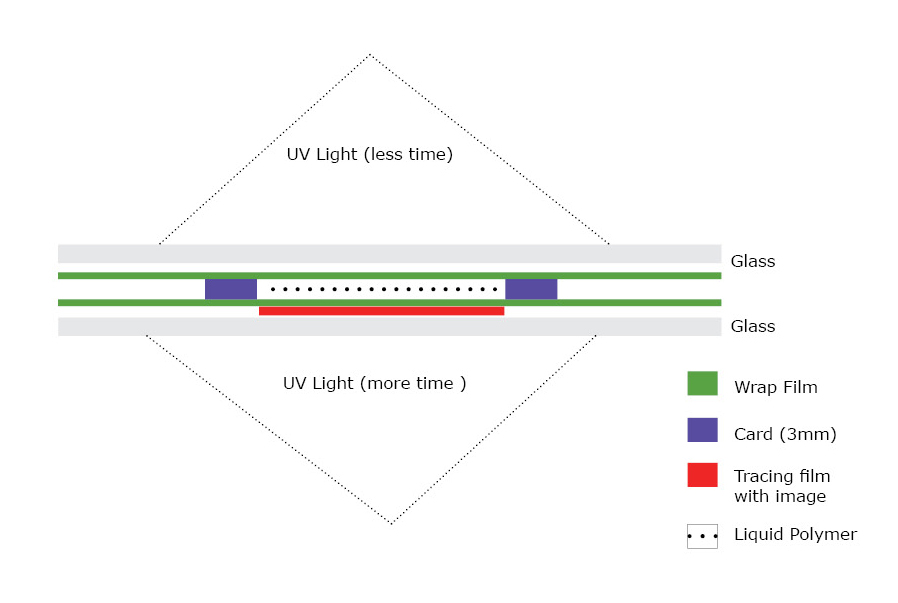

- Liquid Polymer

- Two A5 size plain glass sheets

- Plastic transparent wrap film

- Hard bind pieces 3 mm thickness 4 nos.

- Dishwasher liquid

- Subtract sheet

- 4 clips

- Medium toothbrush

- Tracing sheet with B/W image (Letters white with black background)

Principle: The liquid polymer reacts with ultra violet rays passing through the letter and outline resulting in cross linking of molecules lead to hardening process to form the stamp. Professionals use artificial UV light source from tube light / mercury vapour lamb / metal halide light source with timer. The same process of hardening of liquid polymer is done by using sunlight.

Procedure:

- Making of design with letters white with dark background as shown in the image above.

- Print the image in translucent paper (Tracing sheet).

- Cut the image and place it on the middle of the glass sheet.

- Moisten the tissue with water and lightly wipe on the empty glass area.

- Place the transparent plastic wrap film over the glass and wipe using a thick card so as to fix the image closely to the glass.

- Place 4 cardboard pieces (3 mm thickness) to form a well.

- Pour the liquid polymer inside the well. Remove any air bubbles inside the liquid using a needle.

- Place the subtract sheet about the liquid with rough side facing down.

- Place the transparent plastic wrap film over the subtract sheet.

- Place the second glass sheet and put 4 clips. Observe the readable side (upper side) and the non-readable side of the image (lower side). Now the setup is ready for exposure to sunlight.

- First expose the backside of the setup to bright sunlight (non-readable side) to make a foundational layer (Preferably 11 AM – 2 PM). Correct exposure time is critical for getting good quality image.

- Next exposure to sunlight is done to front side (readable side) of the setup. UV light penetrate through the white letters making the liquid polymer molecules cross linked, hardened, rigid polymer fixed to the background foundation layer. The exposure ratio can be 1:4 – back and front respectively.

- Remove the clip, wrap film and take the stamp out of the glass and place it in a dish, ready for washing out the excess unexposed liquid polymer. Washing is done by any dilute dishwasher solution.

- After washing, cut out the unwanted parts and immerse the stamp body in a small dish containing tap water and expose it again to sunlight for hardening the entire body to make it durable.

- Take the stamp out of the small dish and allow it to dry and is ready to fix to the wooden stamp handle or self inking stamp body using double sided tape.

Hope this experiment is useful for learning the practical application of polymer in day to day life, especially for polymer chemistry students.

– Binoy Jayadevan