Customized printing on ready-made tee shirts can be done by:

- Screen Printing (Need more than 10 Tee Shirts).

- Dye Sublimation Printing (Need polyester tee shirts).

- Direct to Garment Digital Printing. (DTG) (Need costly machines)

- Heat Transfer Printing from Ink Jet / Laser printed Transfer Sheet.

- Vinyl Heat Transfer (Need letter cutting machine).

If you want to print single (or a few) tee shirt with white colour or any vibrant single colour text or graphics, the best method is by using Heat Transfer Vinyl (HTV). Different colours of HTV available online as packet of cut sheets form or as roll. The vinyl film is having a transparent supporting carrier sheet so that the image can be transferred to the tee shirt after cutting and weeding.

Requirements for Vinyl Heat Transfer :

- HTV sheet or film, cut to A4 size.

- Silhouette CAMEO for cutting vinyl sheet.

- Heat Press or Iron box.

- Dark colored tee shirt.

- Weeding tool or pen knife.

- Teflon sheet.

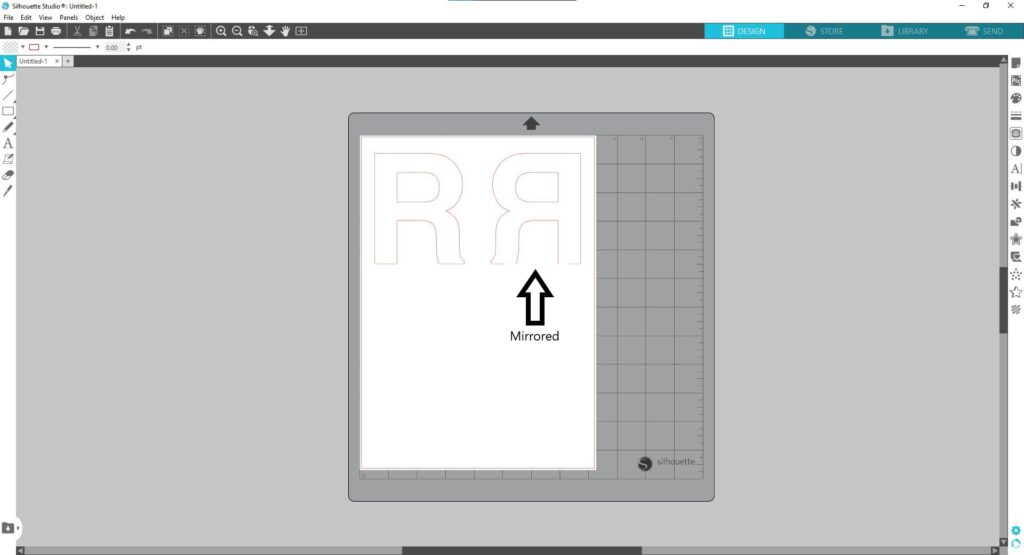

First step is making of the design. You can use Silhouette CAMEO Software or any other software like Adobe InDesign, Illustrator or Corel Draw. Open the graphics in Silhouette CAMEO software and whatever needed to cut appear in the software as red lines. Make sure the image is in the mirror format, this is done by flipping the image horizontally.

Place the A4 HTV sheet on the cutting mat with the vinyl film facing up. Apply uniform pressure to the HTV sheet so that it is fixed firmly to the sticky side of the cutting mat film. Carefully load the cutting mat with the film fixed to the Silhouette CAMEO machine. Upon clicking the send command, whatever seen in the red colour is cut precisely by the cutting knife of the Silhouette CAMEO machine.

Next step is weeding. This is the process of removal of unwanted Vinyl film pieces from the carrier sheet. Weeding tool is available online or use small pen knife. The sheet with text or graphics is ready for transferring to the tee shirt.

If you have heat press machine, transfer of Vinyl to the tee shirt can be done very easily and professionally. Set the temperature to 160 degree Celsius. Place the tee shirt on the platform and remove all wrinkles by applying medium pressure for few seconds. Place the carrier sheet containing texts or graphics on the top of the tee shirt as per your requirement. Make sure the vinyl is facing down. Place Teflon sheet over the carrier sheet. When the temperature reaches 160 degree Celsius apply pressure for about 15 seconds. Remove the carrier sheet carefully leaving the graphics fixed to the tee shirt. If you don’t have a heat press machine, you can use a iron box with flat surface (without holes).

Final image appears with sharp edge far better than screen printing with solid colour. This is an easy method of printing a text or graphics but have solid rubbery feeling. The professionals can transfer multi colour image by fixing single colour vinyl films layer by layer.